Among the lithium battery assembly equipment, there is much different equipment, including battery sorting machine, battery spot welding machine, highland barley paper sticking machine, comprehensive battery tester, etc.

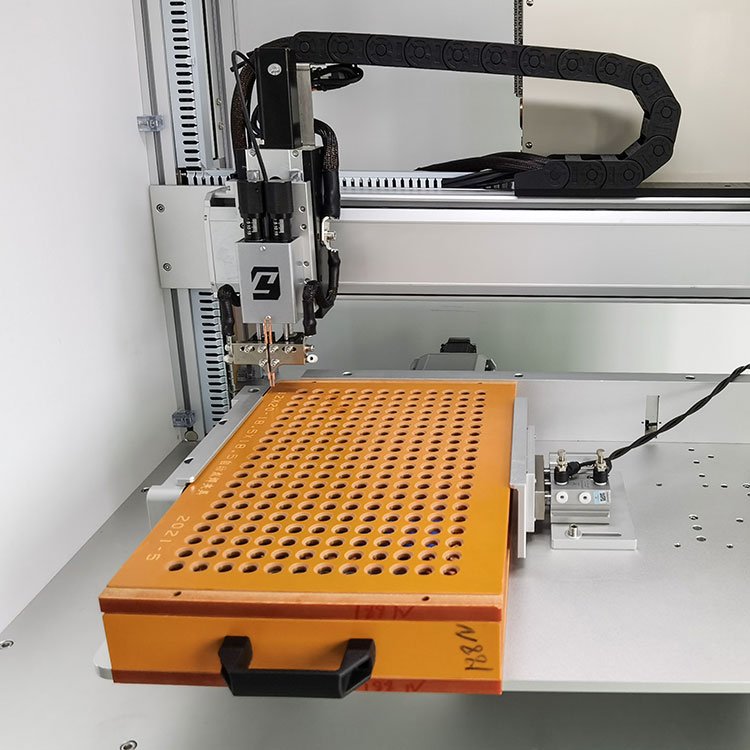

Introduction of lithium battery spot welding machine

No matter what type of battery it is, 18650, 21700, 26650, and 32700 cells are also good, and if spot welding is to keep the battery and nickel-plated steel strip or nickel strip welded, you need to use lithium battery welding machine equipment. During the welding process of the equipment, there are few sparks, no burrs, no discoloration, and the welding is beautiful. The functional performance is stable, and the battery’s appearance is not damaged.

Types of Lithium Battery Spot Welders

It is roughly divided into manual spot welding machines and automatic spot welding machines.

Manual spot welding machine can be divided into pedal spot welding machine (AC pulse welding power supply), transistor spot welding machine (transistor power supply 6000, 8000, 10000A), DC spot welding machine (high-frequency DC inverter power supply).

The automatic spot welding machine includes a single-sided double-station automatic spot welding machine, pure electric double-sided spot welding machine, series-parallel automatic spot welding machine, etc.

Manufacturing principle of lithium battery spot welding machine

Spot welding machine, also known as the resistance welding machine, is the principle of welding by using the resistance heat generated by the current through the welding point of the workpiece. When working, the two electrodes squeeze the workpiece so that the two layers of metal form a particular contact resistance under the pressure of the two electrodes. When the welding current flows from one electrode to the other electrode, instantaneous thermal welding is formed at the two contact resistance points, and the welding current flows instantaneously from the other electrode along the two workpieces to form a loop without destroying the internal structure of the workpiece to be welded.

In the process of spot welding, clean the surface of the weldment, send it between the upper and lower electrodes, and apply pressure to make it in good contact; energize the contact surfaces of the two workpieces to be heated, and locally melt to form a nugget; maintain pressure after power off, The nugget is cooled and solidified under pressure to form a solder joint; the pressure is released, and the workpiece is taken out.

Spot welding process parameters such as welding current, electrode pressure, energization time, and electrode working face size greatly influence welding quality. The process of spot welding is to turn on the cooling water; clean the surface of the weldment, send it between the upper and lower electrodes after precise assembly, and pressurize it to make good contact; energize the contact surfaces of the two workpieces to be heated, and locally melt to form a nugget; After electricity, keep the pressure, so that the nugget cools and solidifies under pressure to form a solder joint; remove the pressure and take out the workpiece. Weldment Preparation and Installation: Before welding steel weldments, all dirt, oil, scale, and rust must be removed. It is best to pickle and blast the weld or remove the scale with a grinding wheel for hot-rolled steel. Although uncleaned weldments can be spot welded, the service life of the electrodes is severely reduced, and the output power and quality of spot welding are reduced. Thin-coated medium and low carbon steels can be welded directly.

How to choose a lithium battery spot welding machine correctly?

In the face of all kinds of different types of battery spot welding machines, some manufacturers are cheap, and some are expensive. Many friends don’t know how to choose because they don’t know. For example, if you need to manufacture high-end battery pack welding, then select a transistor spot welding machine. The standard welding requirements are not too high, and you can directly manually pedal the AC pulse of the spot welding machine.

It should also be noted that when we are concerned about the price of spot welding machines from different manufacturers, we must also understand the welding power source of spot welding machines. In fact, the market price is very transparent, the cost of the welding power source is high, and the welding power source is also essential, which directly affects the quality and effect of the welding battery pack. We are afraid of encountering those bad merchants, such as transistor power supplies, which are also transistor power supplies. The prices of 6000A and 8000A are definitely different. In order to reduce costs, some merchants use shoddy ones. The 6000A is sold when the 8000A is sold, and the customer is deceived.