How To Utilize Laser Cleaning For Paint Removal

Laser cleaning supplies a secure and effective means to eliminate the harmful finishings from targeted locations on ships, planes, lorries, and equipment– without having to resort to the lengthy procedure of setting up environmental protections and personal protective equipment. All required is the laser, laser security drapes, and shatterproof glass. In addition to simple configuration […]

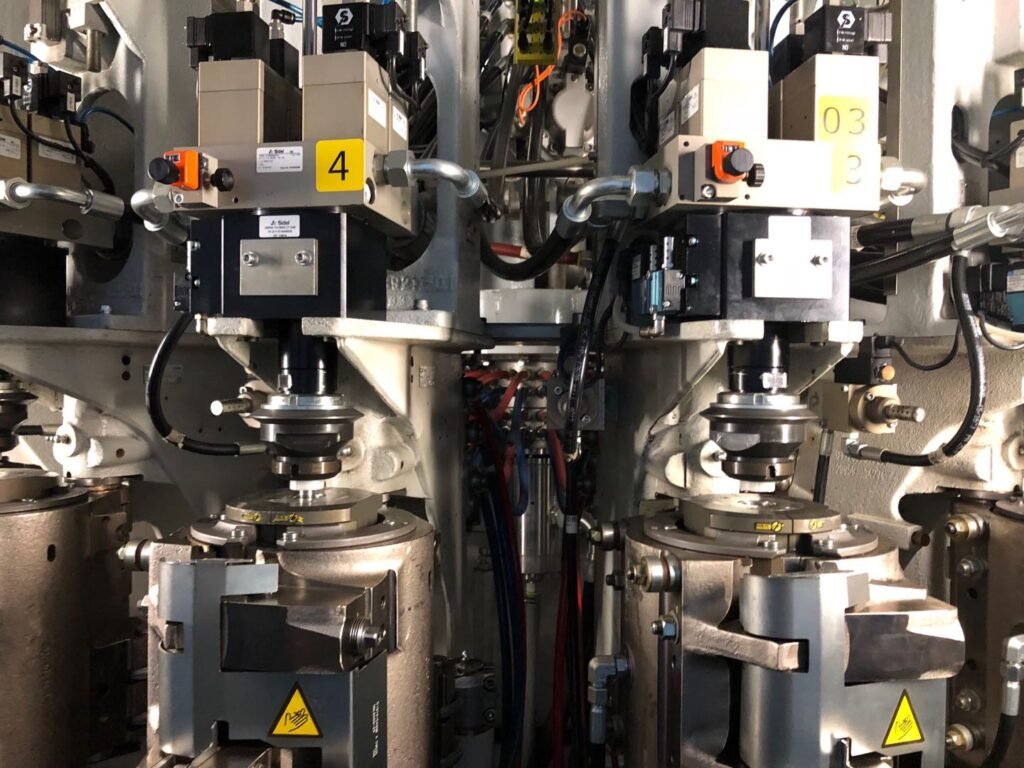

Benefits of Product Automation in A Fiber Laser Cutting Environment

With today’s Fiber laser reducing machines and also their capacity to process a vast quantity of sheet metal daily, maintaining materials at the ready is essential to preserving a constant rate of manufacturing For this reason, it is essential to have some kind of automated product handling and also material storage so that the raw […]

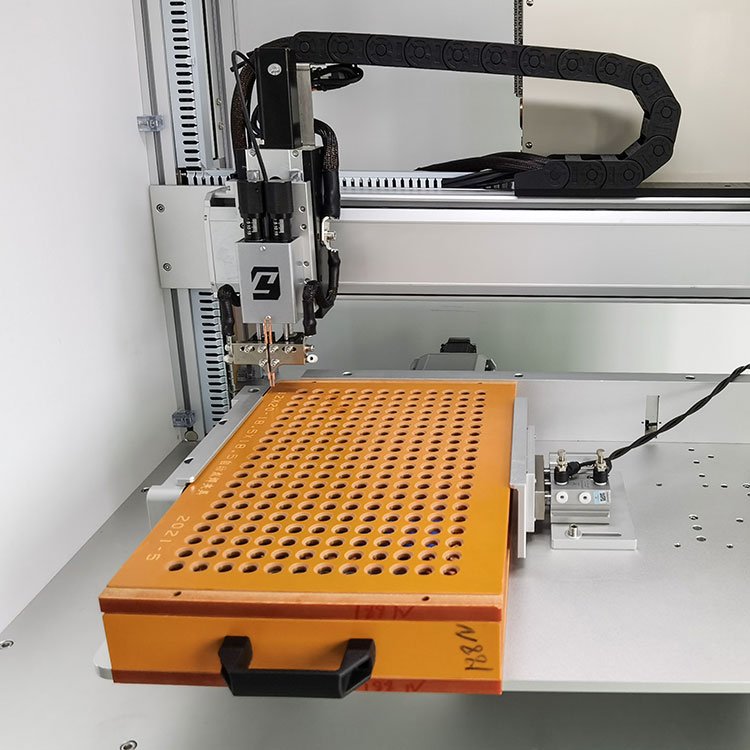

18650 lithium battery spot welding machine production principle

Among the lithium battery assembly equipment, there is much different equipment, including battery sorting machine, battery spot welding machine, highland barley paper sticking machine, comprehensive battery tester, etc. Introduction of lithium battery spot welding machine No matter what type of battery it is, 18650, 21700, 26650, and 32700 cells are also good, and if spot […]

Which industries are laser cleaning machines suitable for?

In today’s increasingly stringent environmental protection regulations and people’s increasing awareness of environmental protection and safety, the types of chemicals that can be used in industrial production cleaning will become less and less. More and more companies choose to use laser cleaning to replace the traditional cleaning mode. Laser cleaning can not only be […]

The principle and advantages of laser cleaning machine

A laser irradiating the surface of the object to be cleaned can produce at least three effects. The principle and advantages of laser cleaning machine are as follows: 01Thermal expansion effectThe difference between the absorption coefficient of a certain wavelength of laser energy between the substrate and the surface contaminants. Its purpose is to make […]

Comparison of laser cleaning methods

Laser cleaning is mainly applied to the surface contamination layer of stainless steel, carbon steel, aluminum alloy, titanium alloy and other metals, semiconductor wafers, ceramics, magnetic materials, plastics, and optical components. The cleaning objects mainly include rust removal and paint removal for industrial fields. , Removal of oil stains, film/oxidation layer, and cleaning of resin, […]

The cleaning application of laser cleaning machine in precision instruments

The precision machinery industry often needs to remove the esters and mineral oils used for lubrication and corrosion resistance on the parts, usually by chemical methods, and chemical cleaning often still has residues. Laser de-esterification can altogether remove esters and mineral oil without damaging the surface of the part. The following introduces the cleaning application […]

Laser cleaning: automatic rotation to clean the inner wall

Cleaning the inner wall of metal has always been a troublesome problem. Traditional cleaning requires manual rotation of the workpiece. The conventional method is suitable for medium-sized workpieces. If it is too large or too small, it is not very relevant. If it is too heavy, it will be more troublesome for personnel to operate. […]

Application of laser cleaning machine in the cleaning of aircraft skin laser paint removal

Aircraft need to be overhauled every five years or so. The paint remover method used now pollutes the environment, harms the health of the operators, and is also expensive. During the maintenance of the aircraft, the paint on the surface of the plane must be removed, and the surface of the aircraft skin must be […]

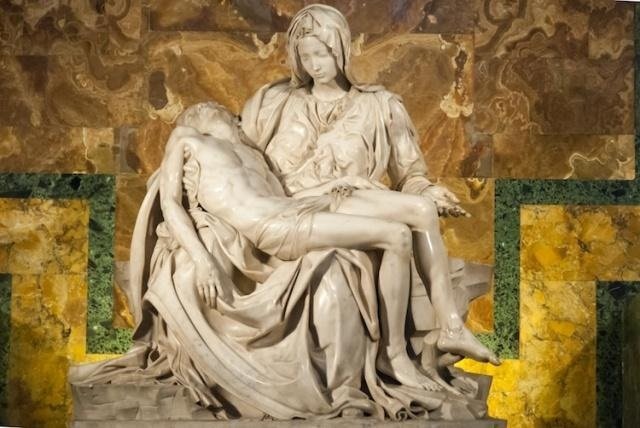

The cleaning application of laser cleaning machine in the restoration of cultural relics

Under the same laser energy condition, the energy density or power density of the laser beams with different spots is different so that the laser energy required for cleaning can be conveniently controlled. The laser can achieve a high degree of concentration in time and space. Laser cleaning uses these characteristics to remove contaminants and […]